SUBSTANTIAL SAVINGS

TIME IS MONEY

AND CAPACITY

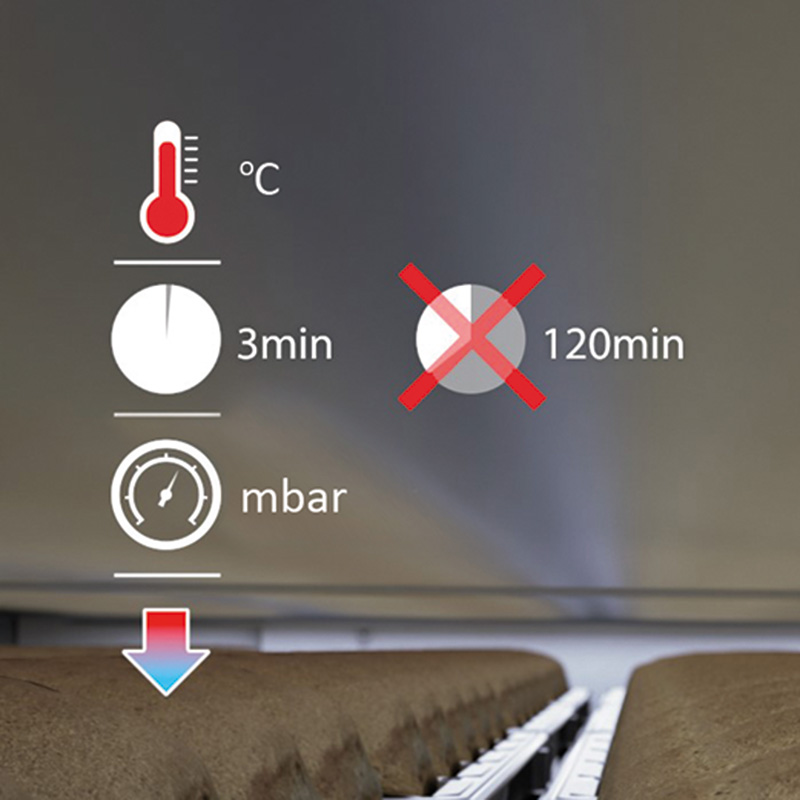

The Vacuum Cooling Process is much less time-consuming than the conventional process. The average cooling time for the products is reduced to 2-3 minutes instead of 60-120 minutes, and the baking time can also be substantially reduced, depending on the product. The ingenious operating system allows a rapid, partly pulsing increase and a controlled decrease in the

vacuum.

Due to the huge reduction in the production time, The Vacuum Cooling & Baking process enables a substantial increase in the production capacity of an average 30% to 50%.

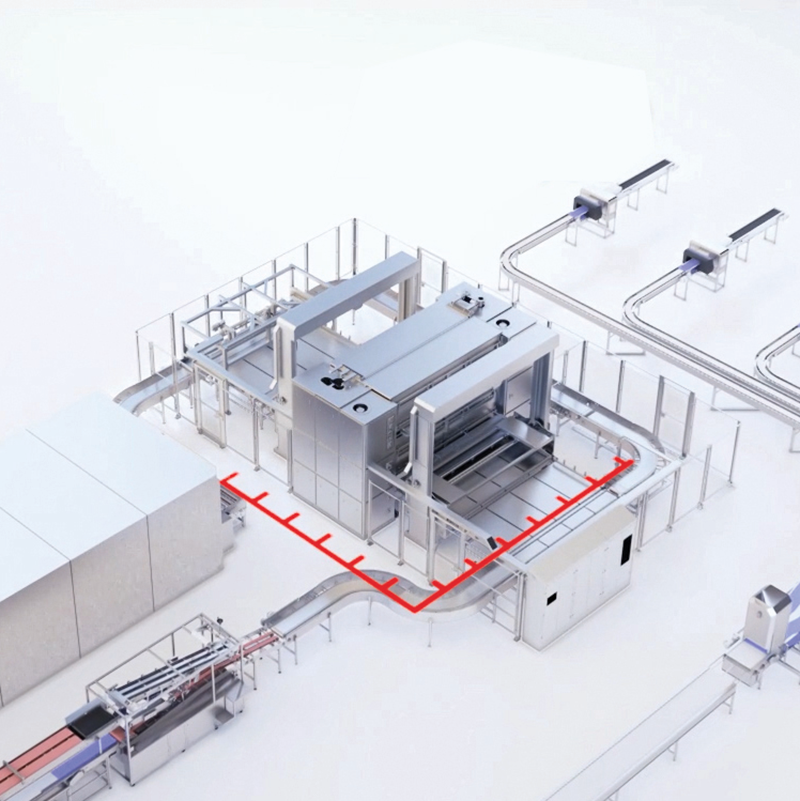

With continuous systems installed in several locations around the world, we have learned that production can be scaled up to quantities of 45,000 cakes (500gr), 54,000 croissants or 12,000 toast breads per hour, depending on the capacity of the preceding production line, the recipes and baking processes.

At the same time the energy costs per unit are reduced, which contributes to a more sustainable production environment. Due to the manipulation of the product moisturisation, the volume is increased and the product is more stable. Less ingredients are needed to produce the same volume and output.

REDUCTION OF BAKING TIME

REDUCTION OF COOLING TIME

SAVING

energy

time

ingredients

space

money

INCREASING

capacity

MORE ABOUT VACUUM COOLING

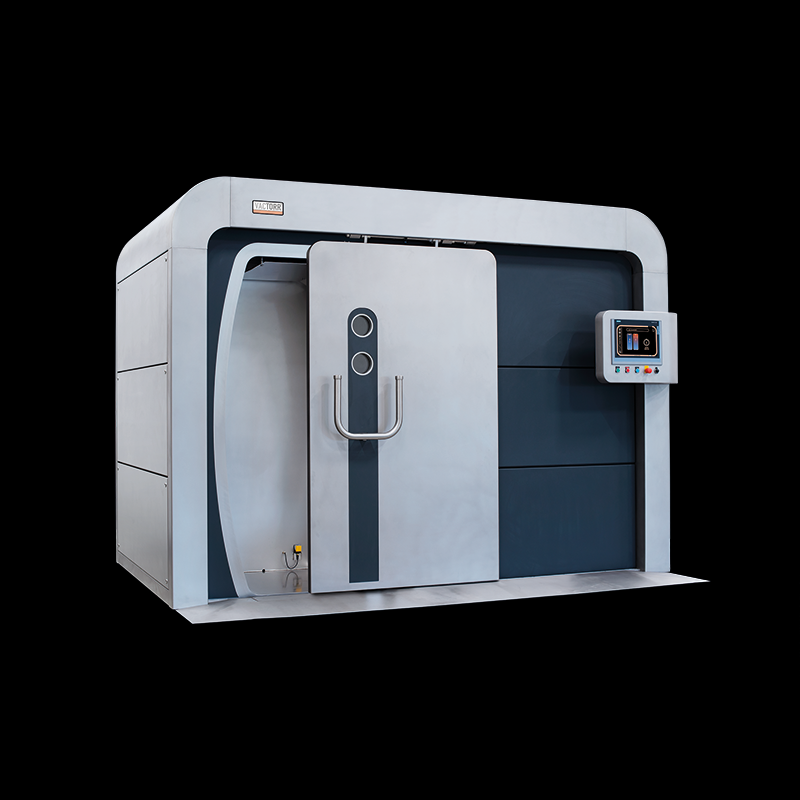

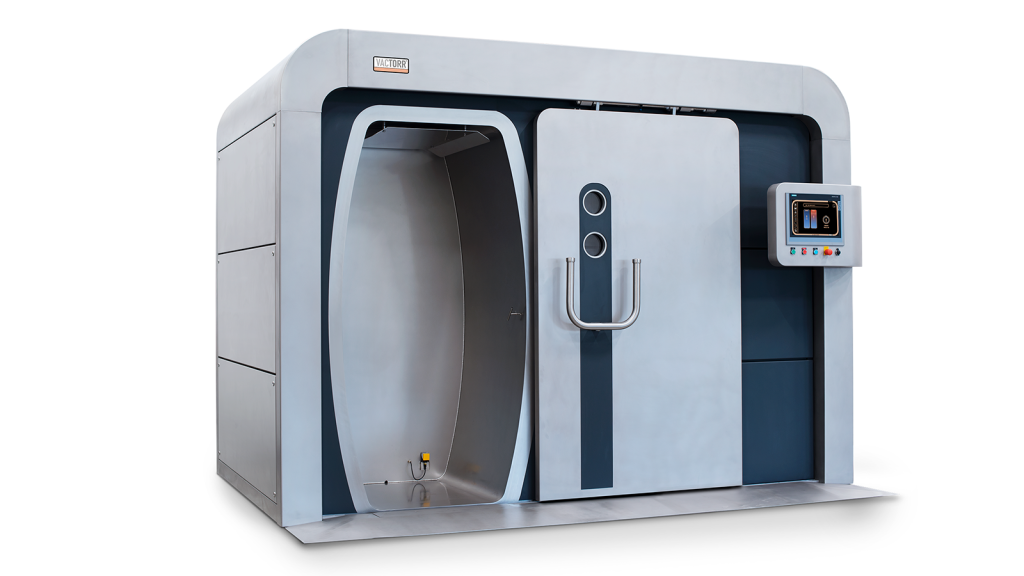

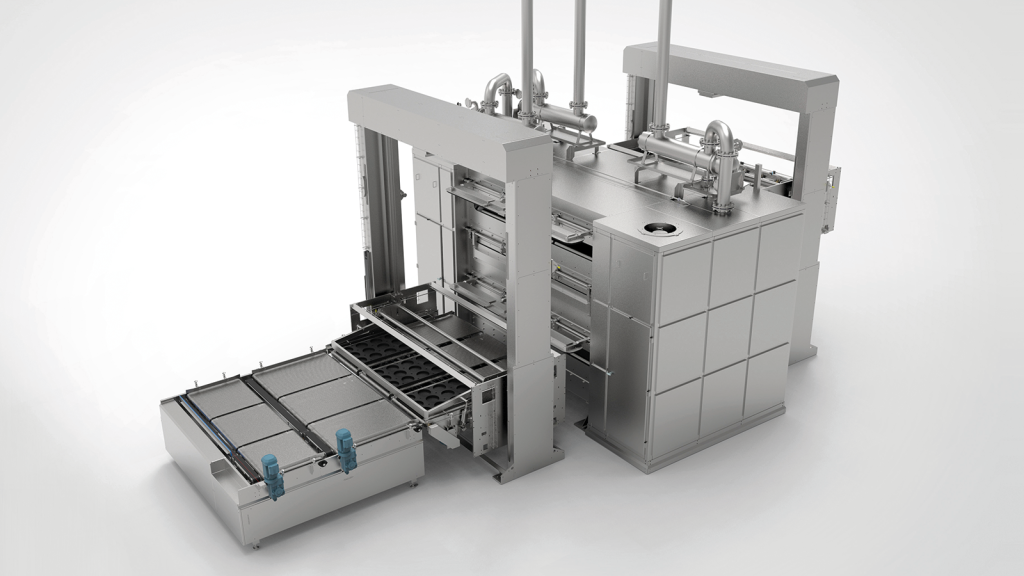

OVERVIEW OF OUR VACTORR FAMILY

This is a fake text. Everything here is just to give an impression of the graphic effect of text in this location. What you’re reading here is a sample text. This will later be replaced by the final text, which is not yet known. The fake text is therefore a text that actually means nothing. The funny thing is, people often read it anyway. Even if they know it’s a fake text, they still read on.

WE ARE HAPPY TO HELP YOU!