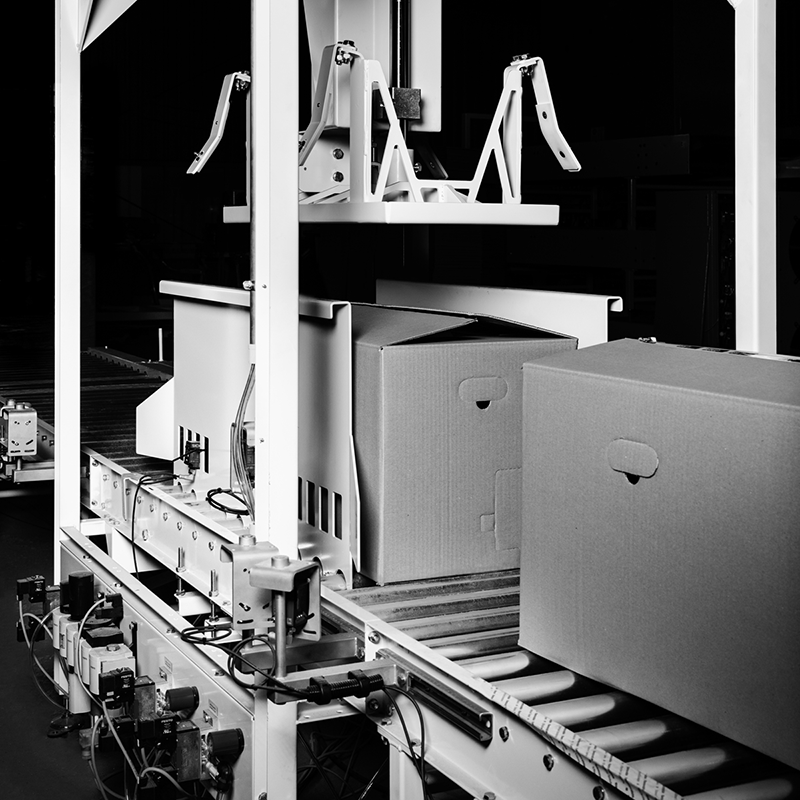

STACKING & PALLETIZING

The final stage in your product’s production run is the palletizing. We offer an entire array of custom machines to help you get your products packaged up in bulk and sent off to your customers.

Do you prefer to put your product units in a box or crate? By a robot or manually? Should the boxes/crates be placed on large, medium or small multilayer pallets of wood or plastic? Would you like multi pallet loading? We offer all these machine solutions and more! We take your palletizing wishes, consider your products and production process and come up with a complete custom build palletizing system to match your needs.

We don’t stop with palletizing machines, because a lot more needs to be done before your palleted products get underway. We offer machines that will strap or stretch wrap your loaded pallets, along with labeling and track and trace options. Finally, we also offer pallet handling and transport solutions to ensure your products reach your customers as quickly and efficiently as possible.

Would you like to learn more about our palletizing solutions and how they can help improve the last leg of your industrial production? Contact us today for more information.

A STRATEGIC DECISION

Packaging bread & pastry products is a complex process that involves many steps. The bakery market is teeming with suppliers of solutions for each of these steps; think about machines for slicing, packaging and labelling bread. Still, in all our years, we have yet to encounter more suppliers that offer the complete solution package that we supply! We provide you with customized turn-key solutions, from product to pallet. Bakepack is your definitive partner for end-of-line solutions and it is this total system integration that makes Bakepack unique.

Industrial bakeries usually purchase several separate packaging solutions, each operating as a stand-alone machine. At Bakepack, we build fully automatic and semi-automatic packaging solutions. We do this by purchasing A-brand packaging machines, then connecting the individual machines in such a way that they operate as one complete system, engineered to meet your production demands.

We have 50 years’ experience at Verhoeven Material Handling Family in building complete internal handling and conveyer systems, both for the food industry and other sectors. Our expert knowledge of dough and dough products is gleaned from over 20 years of experience at Verhoeven Bakery Equipment family. We combine these years of knowledge and expertise and harness it in the packaging process.

In short, at Bakepack End of Line Solutions we provide integrated total solutions that our competitors cannot.

A CLOSER LOOK AT YOUR PRODUCT

Bakepack End of Line Solutions, part of the Verhoeven Bakery Equipment Family, offers you tailor-made solutions to help your end-of-line product packing run smoother. Whether it’s for a dough or bake-off product, those that are baked or with a long shelf life, fresh or frozen. We design and manufacture various packaging lines for your products that fit perfectly in your production line.

We work with all types of products and can accommodate various kinds of processes. The difference in process steps depends on things like environmental conditions, speed, product vulnerability or the number of products. We can also accommodate countless combinations of wants and needs for the final packaging.

At Bakepack, our sole focus is to design the most efficient tailor-made solutions, so that your end-of-line packing activities run as smoothly as possible. This enables you to focus more on your product assortment and your industrial bakery’s production and quality.

WE ARE HAPPY TO HELP YOU!