PRODUCT IMPROVEMENT

“OKAY” TURNED INTO EXCELLENT

‘‘We really embraced Vacuum Cooling and Baking, and we’re very excited about it. Everyone can achieve 60-70% quality, but it’s that last 10-15% that determines the difference between just okay and excellent. When we first heard about this technology, we wanted to learn more. The difference we saw it makes was just incredible.

The visible effect sort of depends on the product group, but in general you could say that, by using this technique and employing this technology correctly, you get a bigger return on the same investment.“

PRODUCT VOLUME

- Increased volume of the cooled product

- Improved texture

- Improved stability

PRODUCT APPEARANCE

- More intensive colouring

- Balanced and equal product surface

- More attractive overall appearance

COMPOSITION AND FLAVOR

- Reduced loss of moisture

- Higher degree of starch gelatinisation

- Possible reduction of preservatives

- Reduction of acrylamide

- Better taste

SHELF LIFE

- Extended shelf life

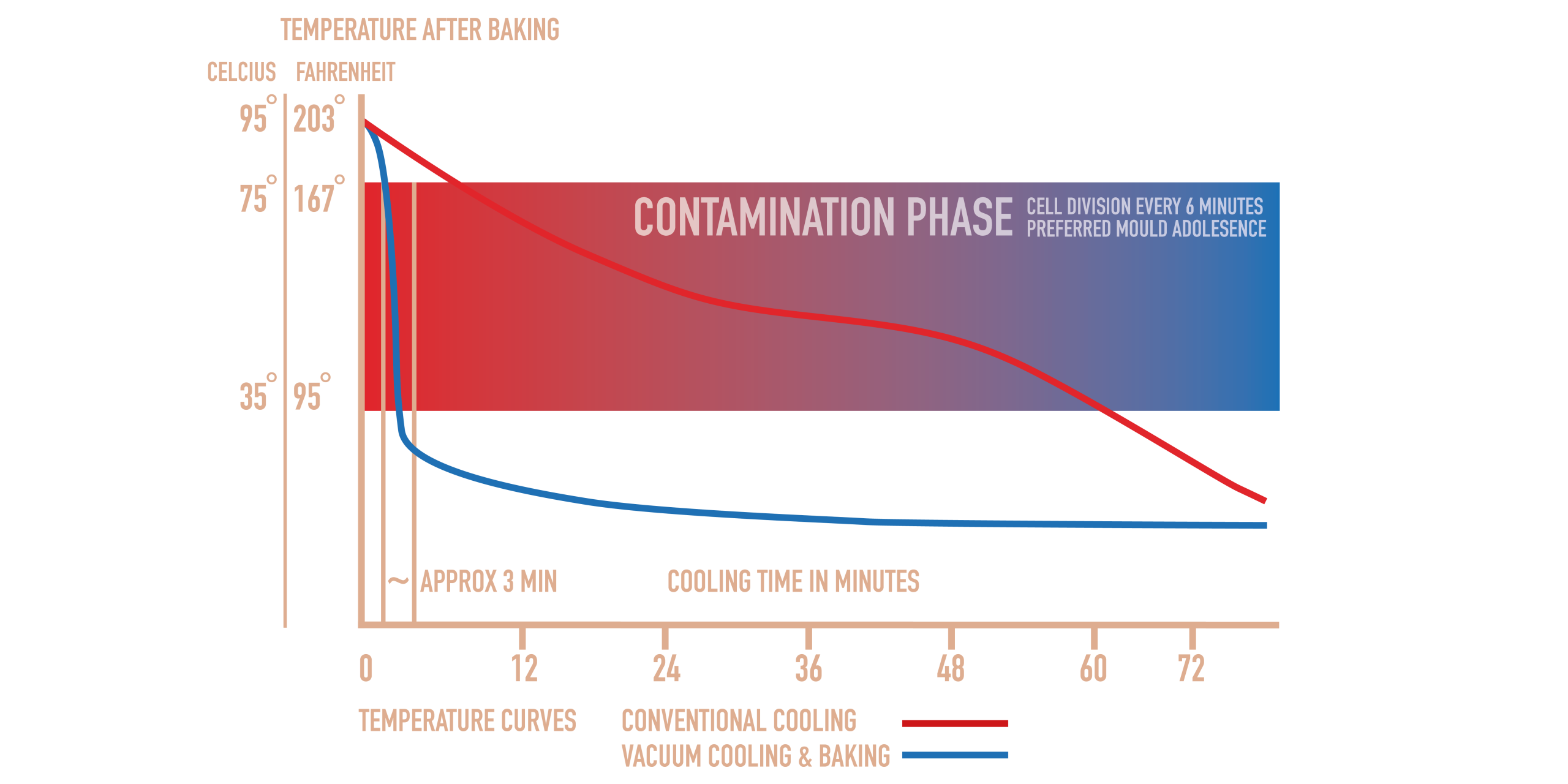

Due to the rapid cooling of the product in the Vacuum Cooling and baking process, the contamination phase (temperature in which the cell division takes place every 6 minutes) is reduced from one hour* to just 3* minutes. The product is healthier and the shelf life is extended (*approximately).

Chris Vreugdenhil

International 3 Star Champion Baker

Owner Vreugdenhil Bakery

MORE ABOUT VACUUM COOLING

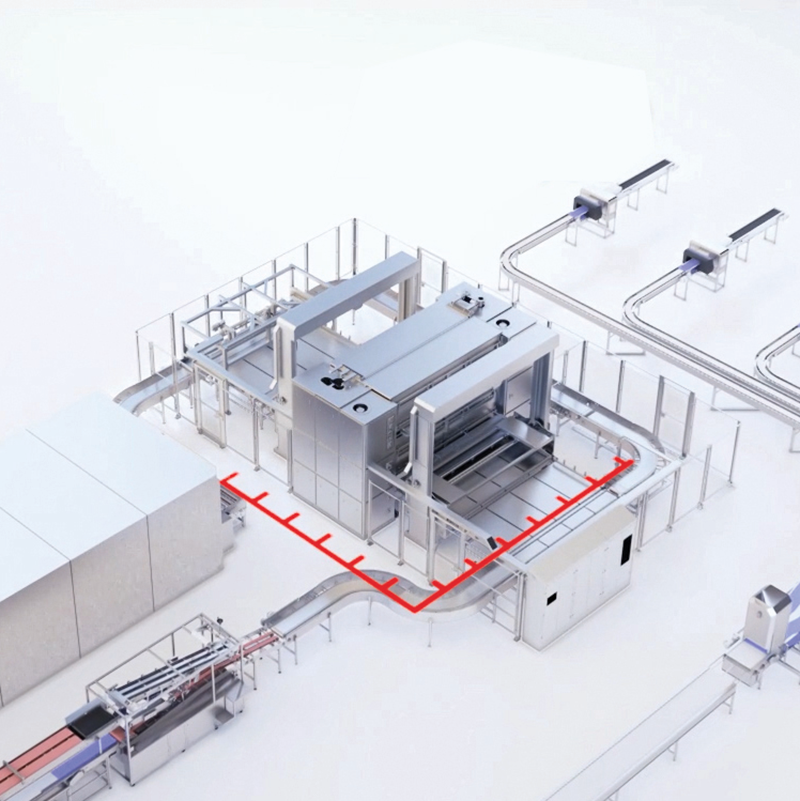

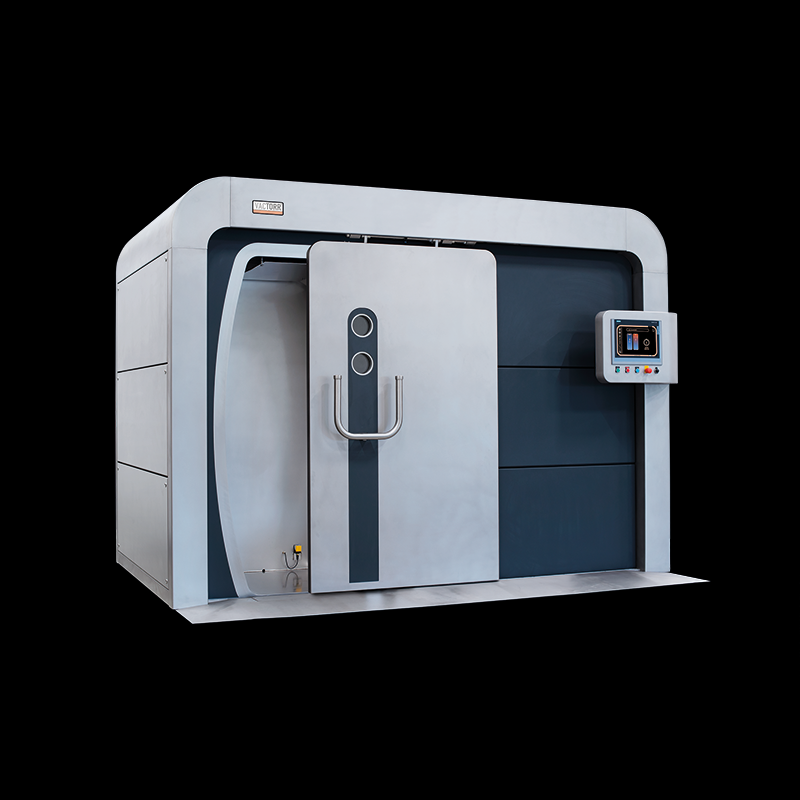

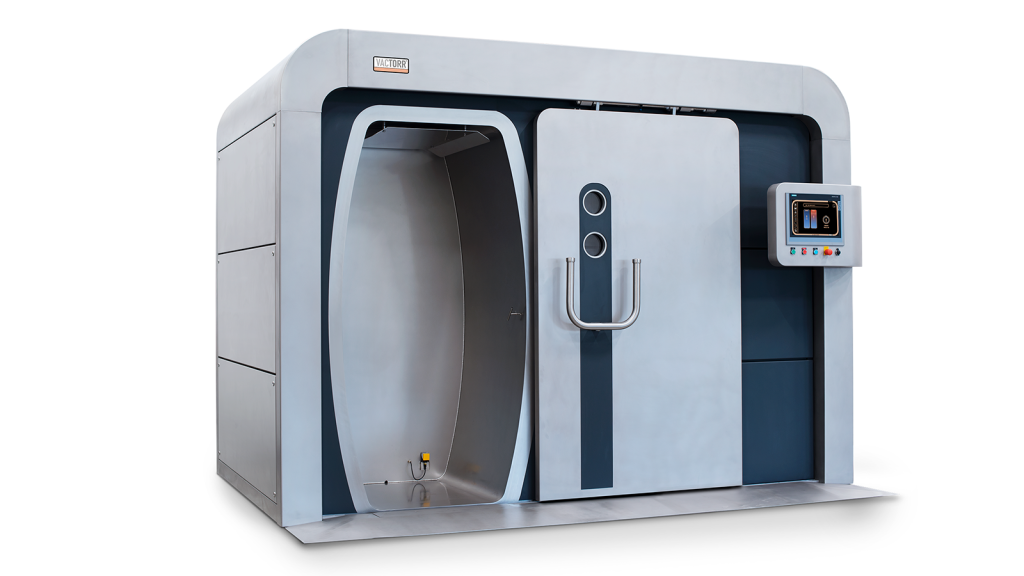

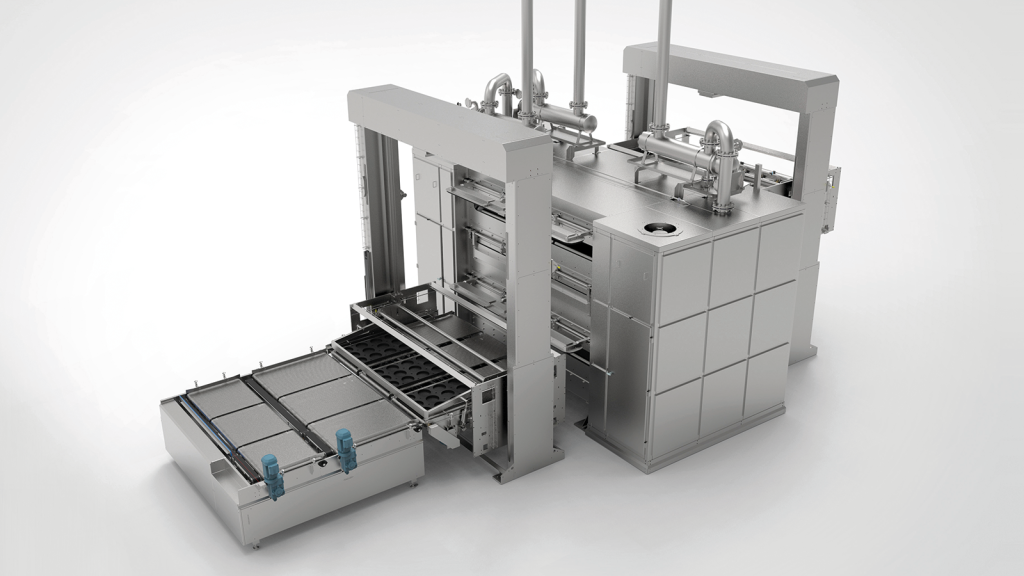

OVERVIEW OF OUR VACTORR FAMILY

This is a fake text. Everything here is just to give an impression of the graphic effect of text in this location. What you’re reading here is a sample text. This will later be replaced by the final text, which is not yet known. The fake text is therefore a text that actually means nothing. The funny thing is, people often read it anyway. Even if they know it’s a fake text, they still read on.

WE ARE HAPPY TO HELP YOU!